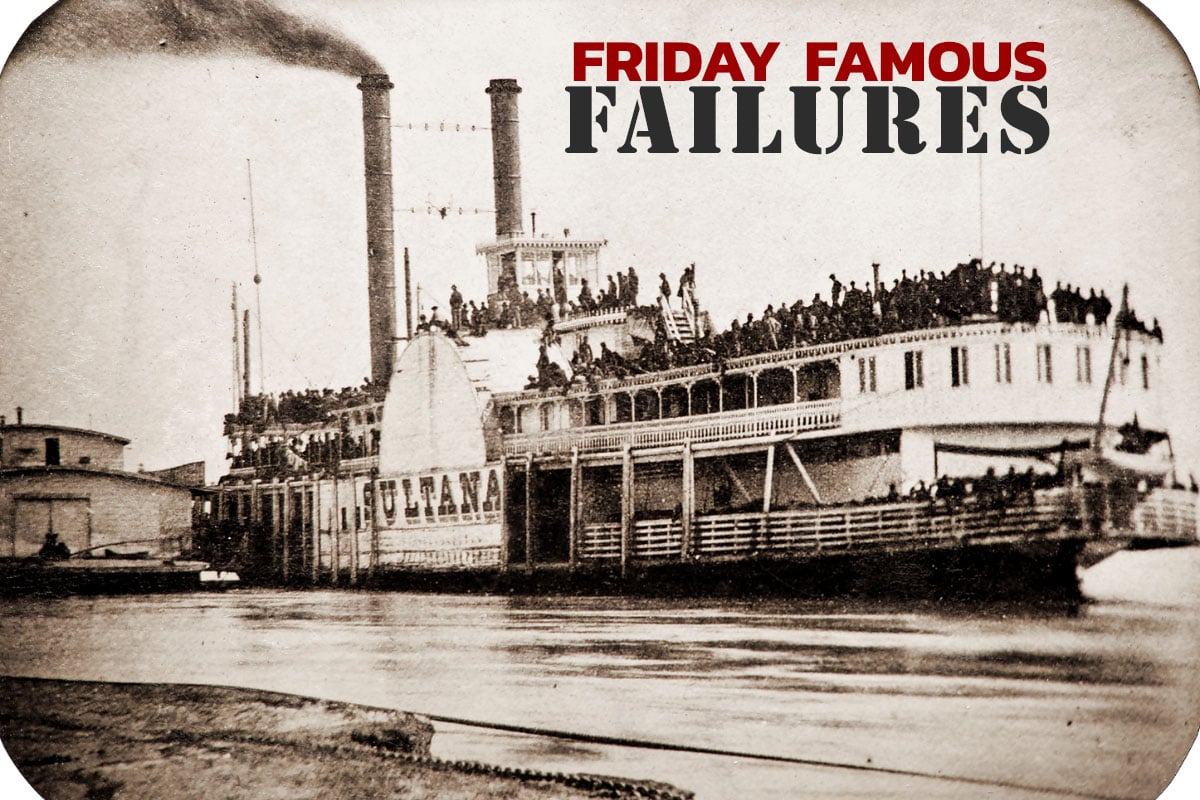

The SS Sultana was an impressive steamboat that ran regular trips up and down the Mississippi River during the Civil War. Then, in the wake of the assassination of President Abraham Lincoln, the SS Sultana exploded, resulting in the deaths of over a thousand passengers—Sultana’s capacity was 376 passengers—and at the time of her explosion, she was carrying 2,137 passengers, many of them recently released Union soldiers. Her explosion and the ensuring tragedy made it the worst maritime disaster in United States history.

Under the command of Captain James Cass Mason of St. Louis, the SS Sultana left St. Louis on April 13, 1865 on a journey to New Orleans. On the morning of April 15, she was docked in Cairo, Illinois when Captain Mason received news that Abraham Lincoln had been shot at Ford’s Theatre in Washington DC. Because telegraphic communication with the south had been almost entirely cut off during the Civil War, Captain Mason grabbed a handful of Cairo newspapers and headed south to spread the news.

When Mason reached Vicksburg, Mississippi, Captain Reuben Hatch, the chief quartermaster at Vicksburg, approached him with a lucrative deal. Thousands of recently released Union soldiers had been brought to Vicksburg to await transport to the north. Hatch told Mason that the U.S. government would pay $2.75 per enlisted man and $8.00 per officer to any steamboat captain who would take a group north. Hatch, who knew that Mason needed money, told Mason he could guaranteed a full load of 1400 prisoners if Mason would give him a kickback. Mason agreed and continued back down toward New Orleans with the promise to return to pick up the prisoners on his way back. On her return trip from New Orleans, Sultana carried with her 70 cabin and deck passengers and a small amount of livestock. She also carried a crew of 85. Yet, 10 hours south of Vicksburg, one of Sultana’s four boilers sprang a leak. Captain Mason was forced to reduce pressure and the steamboat sluggishly arrived in Vicksburg for a boiler repair and a prisoner pick up.

While the prisoners were brought toward the Sultana, a mechanic was brought in to work on the leaky boiler. Although the mechanic wanted to cut and replace a ruptured seam, Mason knew the repair would take days and then he would lose his lucrative passengers. Mason and his chief engineer, Nathan Wintringer, convinced the mechanic to make temporary repairs. Instead of replacing the ruptured seam, the mechanic hammered back the bulged boilerplate and riveted a patch of lesser thickness over the seam. The repairs took only one day, as opposed to two or three. While the repairs were being made, Sultana took on the paroled prisoners. Although Hatch promised Mason 1,400 prisoners, the Union officer in charge of loading placed every man aboard the Sultana.

Sultana had a maximum capacity of 376. When she left Vicksburg on the night of April 24, 1865, she was carrying 1,960 paroled prisoners, 22 guards, and 70 paying cabin passengers and 85 crewmembers for a total of 2,137 people. The SS Sultana was so overcrowded that the decks began to creak and sag. Made worse were the spring floods that had extended the Mississippi river by three miles wide in some places.

Suddenly, at 2:00 am on April 27, 1865, when SS Sultana was just seven miles north of Memphis, its boilers exploded! The first boiler exploded and was followed seconds later by two more. A plume of steam escaped from the top of the boilers and moved outward, tearing through the crowded decks and destroying the pilothouse. Without a pilot, Sultana started to drift. The explosion threw some passengers into the water and destroyed a large section of the boat. The forward area of the upper decks collapsed into the exposed furnace boxes, which soon caught fire and turned the remaining boat into an inferno. Survivors panicked and jumped into the water; however, due to their weakened conditions from being in the prison camps, whole groups drowned together. Within an hour, the southbound steamer Bostana arrived to rescue survivors. Passengers who had survived the initial explosion drifted in the icy water. Many died of drowning or hypothermia. Bodies continued to be found for months. Most of Sultana’s officers, including Captain Mason, perished. The exact death toll is unknown, but is estimated to be 1,168.

What Triggered The Explosion?

The official cause of the SS Sultan disaster was determined to be mismanagement of water levels in the boilers. This was exacerbated by the fact that the vessel was severely overcrowded. As the SS Sultana followed the turns up the river, she would list from one side to the other. Because her four boilers were interconnected, when the boat listed one way, the water would run out of the highest boiler. Despite this, the fires still heated the empty boilers, so when the Sultana shifted the opposite direction, the hot spots would create steam and a sudden surge in pressure. Maintaining higher levels of water in the boiler could have minimized this effect. An official inquiry found that Sultana’s boilers exploded due to the effects of low water, the careening from side to side, and the faulty repair to the leaky boiler completed a few days earlier in Vicksburg.

More recent investigations into the cause of the disaster undertaken by Pat Jennings, the Principal Engineer of Harford Steam Boiler Inspection and Insurance Company, which was founded after the Sultana disaster, found:

- 1) Charcoal Hammered No. 1, which is the type of metal used in the construction of the boilers, becomes brittles with prolonged heating and cooling. While it was the best available material of the day, it was not a suitable boiler material.

- 2) Dirty water of the Mississippi was used to feed the boilers; The mud in the water settled on the plates and surfaces acting as an insulator between the water and the iron. This caused the iron to repeatedly overheat and burn. As noted, this iron gets brittle when it is overheated and cooled repeatedly.

- 3) The construction of the boilers was flawed. The design used 24 smaller flues instead of the traditional two larger flue design. This larger number of smaller tubes arranged closely together made the boilers hard to clean exacerbating the Mississippi River mud settling on the boiler bottom.

Tubular boilers were subsequently pulled from use on Mississippi River steamboats and Charcoal Hammered No. 1 is no longer used in the manufacture of boilers.

Aside from the engineering issues, many have put forth theories of sabotage, including that a coal torpedo struck the SS. Sultana. Many of these theories gained traction because the nation was still very divided and the Sultana carried mostly Union prisoners. However, no evidence of sabotage was ever found and these theories have largely been discredited.

The tremendous loss life on the Sultana created public demand for safer and stronger boilers, and new legislation efforts began. Those involved in steam power also noticed that the huge loss of life due to common boiler explosions (happening as often as every four days in the 1850s) could be prevented if safety improvements were made as larger boilers were being built. The Hartford Steam Boiler Inspection and Insurance Company was founded the following year in 1866. Hartford began supervising construction and installation of boilers in 1879, and produced a widely accepted boiler construction standard known as the “Uniform Steam Boiler Specifications” for all states to adopt.

Extremely interesting situation. Sad are the losses of so many lives. Human judgement and operating error still seems to dominate the cause of the explosion as opposed to the engineering design weaknesses found later in time through an engineering analysis

The boat was “careening from side to side” because of insufficient stability (metacentric height), there being too much weight (too many people) up high and no additional weight low in the hull.

River water was especially dirty when the river was flowing fast. Mud only settles out in calm water.

Amazon Prime offers a documentary on the tragedy. While it does not go into the details of the Boiler failure it is an interesting video

Love this story and always learn more from the failures! Wow

As I recall, this was the birth of what became the ASME Boiler & Pressure Vessel Code.

it’s very sad to see a ship blow up