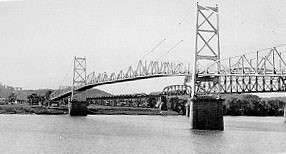

Point Pleasant Bridge, which opened on May 30, 1928, was a 1,460-foot suspension-type bridge that spanned the Ohio River to connect Ohio and West Virginia. This unique bridge incorporated many first-time applications, including the use of aluminum paint, which rendered its silver color. It is the reason why the bridge became known as the “Silver Bridge.”

At a little before 4:58pm on December 15, 1967, in fewer than 20 seconds, the entire suspended portion of the bridge and its two 130-foot towers collapsed and fell into the Ohio River. Of the 37 westbound vehicles on the bridge at the time, 31 fell with it — 24 into the Ohio River and 7 onto the shore. No pedestrians were on the bridge at the time.

The six remaining vehicles were on the West Virginia-side approach. They were stopped behind driver Charlene Wood, who had stopped her car when the bridge started to shake. Hoping to retreat to safety, Wood threw her car in reverse, but it stalled amid the violent shaking. As her car continued to roll backward, Wood witnessed the bridge’s progressive west-to-east collapse. Most of her car had reached the relative safety of the approach when the bridge deck fell from beneath her front wheels, leaving them hanging from the precipice. Wood’s actions prevented other vehicles behind hers from entering the side span and likely saved several lives in addition to her own.

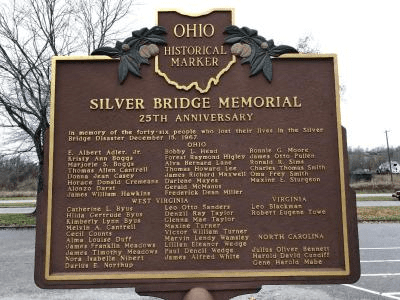

A total of 64 people fell with the bridge (46 killed, 9 seriously injured). Only five survivors were pulled from the 42-degree river. In terms of lives lost, this incident remains the deadliest roadway bridge failure in U.S. history.

Figure 1 – Silver Bridge Memorial Plaque

The Construction of the Silver Bridge

The Silver Bridge’s origin traces back to the early 1900s to Charles Holzer, a doctor who grew tired of the time it took to reach patients on the other side of the river. Some died awaiting his arrival. Holzer eventually organized community groups to plan a bridge. Those groups eventually merged into the West Virginia Ohio River Bridge Company, with Holzer at the helm.

The design for the bridge, prepared by J.E. Greiner Company, called for an elegant suspension bridge comprised of steel wire cables, a distinct stiffening truss system and towers rigidly fixed to their supporting piers. Holzer’s company obtained $950,000 in financing and received three construction bids. The winning bid (the lowest) was from American Bridge Company (ABC) for $892,000. But in their bid, ABC proposed some changes to Greiner’s design.

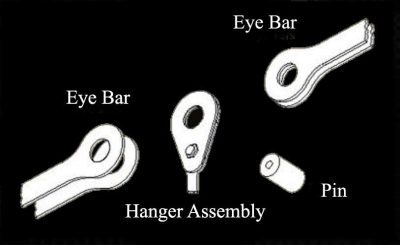

Instead of suspension cables, ABC proposed the use of “chains” of eye-bars that would form links —76 in total — ranging in length from 55 to 44 feet. The eye-bars would be linked together bicycle-chain style, with 11-inch diameter steel pins passing through 27-inch diameter eyelets at the eye-bar ends to form the main part of the suspension system. From these link pin joints, high strength steel hanger bars would support the bridge deck through its truss work.

Figure 2 – Hanger Assembly

Because the eye-bar links would join with a link pin at the top of each tower, the towers could not be firmly affixed to their concrete piers. Instead, they would rock or tip on hinged joints at their base to allow for changes in chain length to accommodate varying bridge loads and temperatures — a first in bridge building in the U.S.

Another notable deviation from conventional bridge design was ABC’s plan for some of the suspension chains to double as the top chord of the trusses that stiffened the roadway deck. Ordinarily, the top chords would be in tension; however, the use of a chain as the top truss chord, when combined with pivoting bridge towers, rendered these members incapable of temporarily supporting the bridge deck in the event of other bridge system failures. Until the construction of the Silver Bridge, neither concept had ever been applied in U.S. bridge construction.

The Investigation

The sudden, complete collapse of the Silver Bridge stunned the nation and initiated the largest structural failure investigation in history, involving federal and state agencies as well as many private laboratories and corporations. It took two-and-a-half years for them to reach their final conclusions.

Meanwhile, many citizens and the media concluded that the bridge had fallen because vehicles in 1967 were heavier than they were in 1928. In the 1920s, a typical car weighed about 1,500 lbs. Trucks weighed no more than 20,000 lbs. By 1967, the average car weighed about 4,000 lbs. and trucks weighed up to 60,000 lbs.

But that was not what caused bridge’s failure. The vast majority of the weight supported by a long span bridge is that of the bridge itself. As such, the increase in live load was relatively insignificant. Despite increased vehicle weights and truck traffic, the Silver Bridge was, on December 15, 1967, carrying only 41% of its design live load and had carried much greater loads prior to that.

To begin the investigation, a 1:5 scale model of the bridge was built. This model, combined with eyewitness accounts, provided valuable clues about the bridge’s failure. To the extent possible and necessary, the bridge was reassembled, incorporating nearly all of the parts that had fallen onto the Ohio shoreline and about 60% of what had fallen into the river.

Investigators already knew that the bridge’s design meant that a complete separation of either the north or south suspension chains at any point on the bridge would have caused the collapse of the entire structure. The question remained, which failed first, and why?

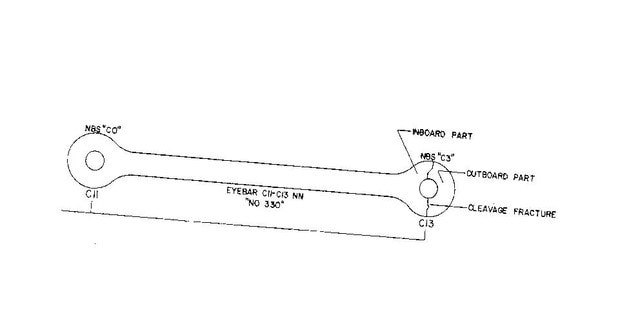

All of the eye-bars from both chains were recovered, and although some were found with varying degrees of fracturing and deformation (clearly caused by the collapse), almost all of them were intact except for eye-bar 330 — its eyelet end was broken off through the link pin hole at joint C13N.

The north chain link pin joint at the top of the Ohio tower was identified as joint C15N. The next two link pin joints in the north chain heading west toward Ohio were joints C13N and C11N. The two eye-bars that formed the link between these joints were eye-bar 330 on the outside edge of the chain and eye-bar 33 on the inside (roadway) edge of the chain.

Figure 3 – Cleavage Fracture

Figure 4 – Eye Bar That Broke

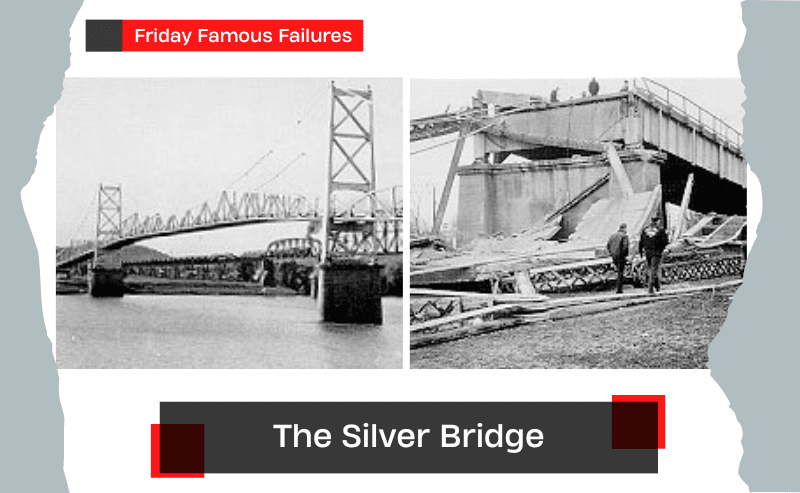

Figure 5 – Silver Bridge Before the Collapse

Figure 6 – Silver Bridge After the Collapse

How and Why the Silver Bridge Collapsed

The investigators were able to determine the following sequence of events that led to the bridge’s total collapse:

- The complete fracture of eye-bar 330 began with the nearly instantaneous brittle cleavage fracture from the link pin hole at joint C13N through to the bottom of the eyelet at approximately a right angle to the bar’s beam section. This initial break would likely account for the gunshot-like sound heard at the start of the bridge’s failure.

2. With its lower section broken through, the now highly overstressed upper portion of the eyelet failed in just one second.

3. This ductile deformation of the upper eyelet section immediately increased by about three inches the north chain’s effective length. This increase in length caused vertical downward deflections of two inches in the center of the main span and six inches in the center Ohio-side span.

4. The six-inch downward deflection of the north truss on the Ohio-side span initiated a rapid increase in the tension stress of the lower chord members of the north truss. This truss was able to momentarily carry a portion of the side span load by simple truss action (due to the residual tension and elastic energy of a half-million lb-ft stored in the eye-bar upper chords of the side span north truss) and prevented the immediate collapse of the Ohio-side span.

5. Now one second past the initial brittle fracture at the bottom of eye-bar 330, it took only an additional 0.2 seconds for its sister eye-bar, number 33, to slide off the now-tilted link pin at joint C13N and completely sever the north suspension chain.

6. At this time (1.2 seconds from the initiating brittle fracture of eye-bar 330), the northern trusses of both the Ohio-side span and the main span were essentially in free fall. The center of the main span had now fallen 16 feet in only one second (free fall velocity) from the time the north chain completely severed (two seconds from the initial brittle fracture).

7. Next, both the main span and the Ohio-side span began to increasingly rotate CCW (as viewed from the west). The south chain had been displaced toward the north by the continuing northward tilt of the Ohio tower, which by this time, was 30 feet north of its normal position at its top.

8. Only four seconds after the initial brittle fracture at eye-bar 330, both towers had tilted or buckled to the extent that the south chain provided no support. By this point, the Ohio-side span had already collapsed and the main span and West Virginia-side span both completed their falls within an additional second.

9. Finally, the West Virginia tower fell — toward West Virginia and slightly downstream.

A mere 8 to 10 seconds had elapsed from the initial brittle fracture of eye-bar 330 to the total silence of the completely fallen Silver Bridge.

Which party bears the responsibility (and liability) for the bridge collapse ? As the article says, Greiner’s design was changed by the Contractor, but presumably the change was reviewed and approved by Greiner. The bridge was in service for almost 40 years. Was metal fatique a factor ?

0ur current bridges are ancient of days. They are ripe for a reprise. Unfortunately, our inspection process has not progressed past 1967. Visual inspection is the norm and typical crack lengths are one tenth to one quarter of an inch. However, NASA long since (circa 1980) determined that visual inspections were not adequate for this size of crack. Modal testing, by contrast, can detect these cracks quite accurately. In one notable case the Space Shuttle was being excited by a 12 pound shaker. The shaker was on the tail, and a loose propellant in the nose (about 190 feet away) was detected by the modal response instrumenation

We have experience with utilization of accelerometers to evaluate structural integrity. The work comprises of short term testing and long term monitoring. We’re learning of the benefit of long term monitoring as analysis favors signs of degradation. This incident is due to brittle component failure cascading to, relatively, instantaneous system failure. I’m not confident monitoring would have identified this weakness though we have identified a cracked flange prior to failure through inspection. This failure may not have been detectible through accelerometer monitoring.

As a WV resident at the time, I recall this collapse and the many lives lost. I believe that there was a fatigue crack initiated in the link pin hole where the cleavage fracture was identified. When the crack reached the critical flaw size, that side of the link fractured near instantaneously, and the opposite side failed from the addition of the bending load. Commercial scanning electron microscopes were rare at the time, and I doubt that one was used in the post mortem fractography. Fracture Mechanics was also not widely understood or applied at the time. I would be very interested in the KIC value of the steel that was used to make these links in 1927! Designs that affect public safety need to be assessed for single point failures, the ability to inspect and find developing problems (like fatigue cracks) before they become critical, and redundancy (FMEAC).

Very similar to the Oakland Bay Bridge Collapse a few years ago. Any chain link Bridge should be inspected for wear and fractures at least annually, with a replacement strategy for the links initiated ASAP.

Clarence R. KREBS PE June 30 , 2032

I have designed bridges for 25 + years. It never said what the span length was , just gave the length of the bridge. I think the mistake was made by not using a proven tested design. They could have used more substructure and shorter spans, and used truss bridge superstructure. My longest span was 900 ft. For two continuous 900 ft spans used steel arch trusses .

Interesting article since I know three bridges built the same way. I did not realize it was an uncommon method. These are the Sixth Street Bridge (Roberto Clemente Bridge), the Seventh Street Bridge (Andy Warhol Bridge), and the Ninth Street Bridge (Rachel Carson Bridge) in Pittsburgh, PA crossing the Allegheny River and connecting Downtown to the North Shore. They are known as the sister bridges because they are nearly identical and sit in close proximity. According to the Historic American Engineering Record, these are three of the few remaining eye bar chain suspension bridges in America.

American Bridge Company (ABC) was, and still is, based in Pittsburgh. Although it has gone through some ownership changes over the years. ABC built the first of the sister bridges the same year as the Silver Bridge. However, the sister bridges seem to have redundancy to avoid the single point failure of the Silver Bridge. Instead of two eye bar links per pitch of chain, the sister bridges seem to have no fewer than eight eye bars per pitch of chain.

My review is very brief and high level. But it makes me wonder why the same firm built two bridges of the same type at the same time, which according to this article was a new concept, but with such a noticeable difference.

All of the above comments seem much more plausible than the wVA urban legend about a mysterious super human Mothman creature seen fllying around and, landing on the bridge ust priop to the collapse.

This is my second comment. I think the center span was 700 ft long .and the other two spans were 400 ft each. So with out a doubt this is an error to use a suspension bridge design , in my opinion .

It should be a stiff truss without all the uplift flexing of the suspension bridge.

Clarence R KREBS PE 10/2/2023

In my previous comments I never gave consideration to the”date” this was designed. The experience with the interstate highway program volume has helped the quality in selection of bridge type. The longer the span the more expensive per square foot. So you balance the substructure cost with the superstructure cost. There may be a set navigation span requirement, then that sets the span length , regardless of cost.

The suspension bridge now is considered only when the span is too long for a truss. In my opinion .

The terrible bridge disaster in Baltimore this morning brought back a chilling memory, and a thankfulness to God of His protection. I remember this very well, as a family, in the summer of 1967, we were traveling to the east coast to see my grandmother and aunt and uncle…..my mom’s family. Along the way we were stuck in a traffic jam on a suspension bridge in West Virginia. My mom became very uneasy, and said she didn’t feel the bridge was safe to be on. I can remember it shaking, while we were in the car. I thought my mom was just nervous because she didn’t like heights. Or water. But later that year, before Christmas, the Silver Bridge we were on was in the news. It collapsed, killing over 40 people. I remember my mom mentioning that this was the bridge we were on just about 5 months prior. I thought of this as I seen the horrible video of the Baltimore bridge collapsing and realized that our lives are always in the balance. God’s grace was on us that summer…..it could have happened then. But it didn’t. The Word of God says in James 4:14 “Whereas you do not know what will happen tomorrow. For what is your life? It is even a vapor that appears for a little time and then vanishes away.” We often do not know when our live here on earth will end. This is why it is so important to make sure you have given your life into the hands of our Savior, Jesus Christ, for His guidance and protection…..and most of all…..eternal life. I’ve been thinking of this Baltimore tragedy all day long, and praying for those affected by it. It is only by God’s grace we are spared. Let’s not trample on life…..it is precious.