Sandblasting is commonly used to prepare a surface prior to painting and to strip paint from machinery and metal. It is also used to produce the lettering and engraving on most modern cemetery monuments and markers and to clean boat hulls, brick, stone and concrete. Sandblasting can occur naturally—usually as a result of particles blown by wind, causing aeolian erosion—or artificially, using compressed air. But, while it’s a cleaning method for industrial and commercial structures, it is rarely used to clean non-metallic surfaces.

The abrasive blasting process known as sandblasting was patented by Benjamin Chew Tilghman on October 18, 1870 and is called “sandblasting” because it blasts the surface with particles of sand. Thomas Wesley Pangborn perfected the idea and added compressed air in 1904. As the sand particles strike the surface, they create a smoother and more even texture. The effect is similar to that of using sandpaper but provides a more even finish with no problems in corners or crannies. Over the years, several other materials have been used in place of sand in sandblasting, including steel grit, copper slag, walnut shells, powdered abrasives and coconut shell.

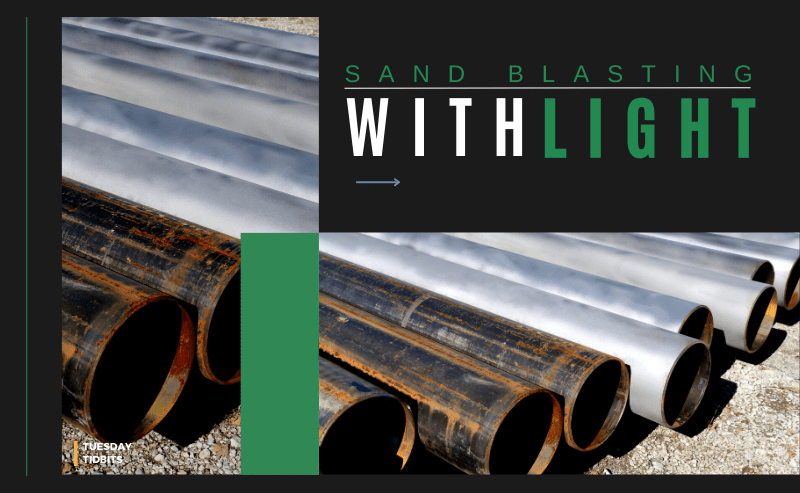

Laser Light Sandblasting vs. Traditional Sandblasting

Now, laser light is being used for “sandblasting.” Laser light sandblasting is gaining increasing in recognition and use as it rapidly expands around the globe, as laser beams can now clean and structure surfaces more precisely and cost-effectively and in more environmentally-friendly ways than conventional systems have done. The replacement of sandblasting by laser cleaning is inevitable as it offers a number of advantages. The laser light pulse is strong enough to clean rust and paint from metal, and the removal of coatings takes place by evaporation, which prevents damage to the surface. Moreover, laser light cleaning not only allows for the removal of old coatings but also enables the development of the surface for polishing.

With conventional sandblasting, sharp-edged sand particles tear away parts of the surface, causing the sharp edges to wear away and mix with the resulting dust. Ultimately, the mixture must be disposed of as special waste, which pollutes the environment and incurs additional costs. Sandblasting with light eliminates that waste, making it a much cleaner process. And that leads to an additional advantage of laser light sandblasting: the fact that the work area does not need to be protected from unwanted sand particles.

Laser light sandblasting delivers all the advantages of sandblasting without the risks and hazardous waste, which means it promises a healthier future for those who perform the process. This is particularly important in the textile industry, where traditional sandblasting has been known to cause silicosis in workers. Silicosis is a form of occupational lung disease caused by inhalation of crystalline silica dust. It’s a type of pneumoconiosis marked by inflammation and scarring in the form of nodular lesions in the upper lobes of the lungs. And it’s untreatable.

Dr. Kenneth Rosenman, a professor of medicine at Michigan State University has found that silicosis deaths represent 4 to 8% of the silicosis cases per year. Based upon these estimates, some 2,500 to 5,000 cases could be occurring each year.

LIGHTblast Sandblasting

Fraunhofer Institute for Material and Beam Technology (Fraunhofer IWS), a Dresden-based developer of complex system solutions in materials and laser technology, has developed a technology called “LIGHTblast” for sandblasting, which is now being introduced in the semiconductor manufacturing, automotive supply and other industries.

Fraunhofer IWS uses high-energy light instead of sand grains to clean and roughen surfaces. For this purpose, researchers developed the laser-based process LIGHTblast, which accomplishes cleaning and structuring tasks significantly faster than conventional processes and should result in lower operating costs in series production.

The process can also be automated more easily with positive effects on quality, process control and occupational safety. In addition, the system works much more precisely than a sandblasting system, as a laser beam with a diameter of less than 50 micrometers (i.e. thousandths of a millimeter) replaces a particle stream several centimeters wide.

There is compelling evidence that points to the future of high-energy laser light sandblasting technology such as LIGHTblast:

- 100 times faster than known micro-structuring, with processing speeds of up to 10 cm²/s

- Simple substitution through use of identical media connections as for sandblasting system

- Avoidance of blasting media and masking prevents component contamination, waste and operating costs

- Definition of surfaces to be processed via CAD at the click of a mouse

- Roughness precisely selectable from Rz= 2 µm to 200 µm

Apart from cost and quality benefits, the ecological balance of manufacturing processes is becoming increasingly important for many industrial users. Thus, many pre- and post-processing steps are eliminated. The light-based processing does not require any chemicals for cleaning. It precisely processes only the desired surfaces, consuming neither sand nor material for masking, thus saving hazardous waste and adhesive tape waste. The laser beam vaporizes parts of the surface; the expanding vapor carries away solid components and also achieves a defined roughness.

Thanks for information. Good general information.

What about the energy (carbon foot-print) required to perform compared to sand-blasting and the capital cost of laser compared to sand. There are plenty of new technologies that claim to be ‘better’ but in the end are not as green as originally thought.

Very interesting development! What are the environmental and health implications of the vaporized material and how does that compare with the solid waste created with the conventional media blasting approach? I would assume that there are some hazardous byproducts of light blasting coated materials and potentially some hazards associated with light blasting of chrome bearing stainless materials.

Great idea and interesting article

Interesting.

One would expect an “evaporated” and recondensed material to have a smaller particle size distribution compared to mechanically generated particles. And smaller particles — even if the material is not hazardous itself — are often hazardous (e.g., PM10, PM2.5).

The smaller size particles from “evaporation” of the coating seem especially problematic when the coating to be removed is hazardous itself (e.g., lead paint) .

Coarse dust releases from conventional sandblasting are well-controlled by dust bags installed on the ventilation exhausts.

How does the laser system accommodate air pollution controls?

How well is the “evaporated” / recondensed coating controlled by bag filters?

How does that compare to the mechanically generated / coarse dust waste from sandblasting?

Sandblasting can have several positive side effects that laser ablation might not.

First, it can leave the surface a little rough which can aid in paint adhesion,

Second, it imparts a residual compressive stress to the metallic surfaces which can help prevent fatigue cracking. This can also be achieved by steel shot blasting.

How is the evaporated waste captured and processed? How are the workers protected from the laser beam(s)?

It is amazing how technology is evolving even for items / activities that may appear to be insignificant to many of us. However I am curious in that the Article indicates that Laser light sandblasting delivers all the advantages of sandblasting without the risks & hazardous waste. Will it be used to remove existing lead based paint on Bridges, steel, etc. or is it limited to shop applications.

I’d like to know about the possible environmental and health hazards posed by the paint microchips and the evaporating coatings

It’s interesting to note that laser light sandblasting offers all the benefits of sandblasting without the dangers or hazardous waste, meaning that individuals who use it may look forward to a healthier future. This brings to mind the worn-out, weathered surfaces of my dad’s warehouse, which has seen better days due to years of wear and tear. He’s searching for a commercial sandblasting service since he wants to revitalize the area and increase its efficiency. Sandblasting appears to be the best approach to remove old paint and dirt layers from surfaces and prepare them for a new coat of paint.