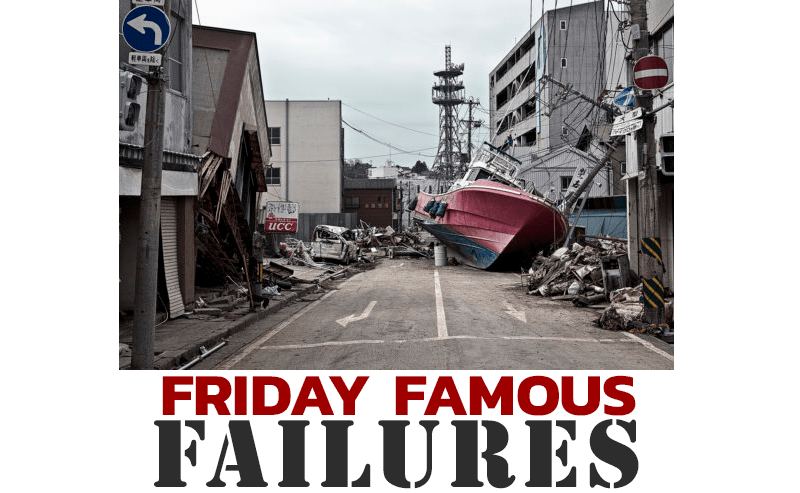

On March 11, 2011, the strongest earthquake ever recorded in Japan struck off the coast of Honshu island. Measured at 9.0 on the Richter scale, it demolished buildings and generated a 14-meter tsunami that flooded coastal cities. Nearly 20,000 people died.

As Japan attempted to cope with the physical destruction, flooding, and death caused by the earthquake, disquieting reports from Tokyo Electric Power Company (TEPCO) warned of small radiation leaks from its Fukushima Daiichi nuclear plant. As time went on, however, it became clear the “small radiation leaks” were actually a large-scale containment failure that would spread radioactive contamination all across Japan and the world–leaks which, in 2022, yet continue.

In the words of the Japanese Commission that investigated the disaster, “How could such an accident occur in Japan, a nation that takes such great pride in its global reputation for excellence in engineering and technology?”

The Daiichi Plant

The Daiichi plant was built on a bluff on the coast of Fukushima Prefecture in the late 1960s. The bluff was originally 35 meters above sea level but was excavated down 10 meters above sea level so the plant could be built on more stable bedrock. Additionally, 14 meters of earth were removed for the basement of the plant.

For the plant, TEPCO bought blueprints “as-is” from General Electric (GE)–then a world leader in nuclear reactors–for a Light Water Reactor. This type of reactor uses heat from a nuclear chain reaction to create steam, which then powers a turbine to generate electricity. Water is pumped through the reactor as coolant and vented as steam to run the turbine.

In the event of a meltdown, the cooling pumps flood the reactor vessel, absorbing neutrons (arresting the chain reaction) and cooling the reactor core. Backup power in the form of emergency diesel generators and batteries was, per the GE plans–which were designed for reactors in the United States, where earthquakes and tsunamis are rare–located in the basement of the plant.

TEPCO did consider the possibility of a tsunami and built the plant to withstand a tsunami of 3.1 meters. After new information emerged in 2002, they upgraded the facility to withstand a 5.7-meter tsunami.

As constructed, the plant was compliant with the level of seismological knowledge and standards of 1967. Later research showed that, as built, the plant was vulnerable to tsunamis and core damage, and–under new regulations released in 2006–TEPCO was required to review the safety of its plants. In response, they sent limited assessments to the regulators, who accepted them without question, in 2008 and 2009.

Yet by 2006, regulators and TEPCO engineers knew there was a possibility of a tsunami exceeding the height of the ground level of the plant and the consequent risk for electrical failure, reactor core damage, and contamination release if seawater pumps broke down. But TEPCO chose to employ an “arbitrary interpretation and selection of a probability theory” and a “biased calculation process” to classify these risks as minimal and did not take measures to prevent the disaster.

Causal Factors of the Disaster

Low height of the plant above sea level: This was ostensibly to mitigate vulnerability to earthquakes by allowing the facility to be built on bedrock. It was also, however, the result of a cost-benefit analysis performed by TEPCO, who “decided to build the plant at ground level after comparing the ground construction costs and operating costs of the circulation water pumps.”

Location of the emergency power system: The emergency power systems, diesel generators, and batteries, were located in the basement and were flooded by the tsunami. The prolonged loss of emergency power shut down the cooling and venting process and knocked out controls, causing the plant to fail to contain radioactivity.

Lack of sufficiently detailed procedures: There were no clear standards governing whether the equipment was suitable and unclear procedures for reporting problems. The existing manuals gave engineers wide latitude in judgment, and the corporate culture did not enforce published ethics standards. The plant even lacked equipment schematics, which delayed effective response during the disaster.

History of safety problems: In 2003, a government-ordered investigation found 16 cases of serious misconduct from 1986 to 2001, including the failure to report cracks in the containment shroud, failure to keep records, and falsified records.

“Ingrained conventions of Japanese culture.” Identified by the Japanese Commission, this included:

- Reluctance to question authority. After the disaster, The Japan Times reported that many Daiichi engineers were concerned about the placement of the emergency power systems in the basement, but they did not challenge the company’s order not to alter the blueprints purchased from GE.

- Collective mindset. The perceived first duty of any Japanese individual is to defend the interests of his organization. After the disaster, an official told a newspaper that the plant did not receive upgraded tsunami safety features or have the emergency generators relocated because doing so would have been regarded as criticism of prior decisions.

- Devotion to “sticking with the program.” The engineers considered that the maintenance of a stable energy supply was their primary objective, so they didn’t report problems or concerns for fear that the facilities would be shut down due to regulatory delays. Engineers were also defensive about reporting minor problems because of the risk for sensationalism by the media.

- Groupism and insularity. Engineers, confident of their understanding of nuclear power, eventually concluded that they did not need to report to regulators as long as they maintained safety. They came to believe that they were not permitted to report problems and actually deleted data or falsified inspection and repair records. “The [Engineering] division became a homogeneous and exclusive circle of engineers who defied checks by other divisions.”

Effects of the Disaster

When the tsunami incapacitated the Daiichi plant’s cooling systems on March 11, the reactor core began generating excessive heat. Engineers delayed using seawater to cool the reactor in order to protect the plant equipment from corrosion, which caused pressure in the reactor and containment vessels to exceed the design pressure and resulted in several hydrogen explosions between 12 and 15 March. These explosions severely damaged building and containment structures.

As a result, the Japanese islands were contaminated with radioactive fuel, water, debris, soil, and other waste. Radioactive particles were blown downwind from the plant and spread to other countries, and radioactive seawater has washed up on the shores of continents around the Pacific.

Initially, TEPCO publicly downplayed the severity of the situation, failed to disclose the increase in radiation leakage, and concealed its ongoing containment problems. Withholding this crucial information from residents, regulators, and the international community made the situation significantly worse.

The damning conclusion of the Japanese Commission is as follows:

Although triggered by … cataclysmic events, the subsequent accident at the Fukushima Daiichi Nuclear Power Plant cannot be regarded as a natural disaster. It was a profoundly manmade disaster – that could and should have been foreseen and prevented. …[This] report catalogs a multitude of errors and willful negligence that left the Fukushima plant unprepared for the events of March 11.

Radioactivity continues to leak from the Daiichi plant as of this writing in 2022.

the date of 2001 is incorrect. The actual year was 2011. Big difference and affects the rest of the report dates presented herein.

Thank you! The post has been updated with the correct date.

Your statement that the cooling pumps flooding the reactor vessel is to absorb neutrons is not correct, water is not a neutron absorber.

Also the ability to keep cooling flow is to remove decay heat from the core to prevent a core meltdown. You need to keep cooling flow until the decay heat generation rate can be compensated by losses to ambient.

I think you have a typo in the opening sentence the earthquake hit March 11th 2011 not 2001.

Thank you! The post has been updated with the correct date.

Year was 2011

Thank you! The post has been updated with the correct date.

It was March 11, 2011 the accident occurred not March 11, 2001 reported in the article.

Thank you! The post has been updated with the correct date.

This event actually happened in 2011, not in 2001. At first, I thought it was an earlier event and couldn’t believe it had happened a “second time”, but its just a typo. Still a very terrible cascade of mistakes with consequences even today!

Thank you! The post has been updated with the correct date.

Title says Daachi, not Daiichi.

Thank you! I have edited the title to correct the error.

One of the key issues involved in the disaster as it panned out was carefully detailed in an enactment showing how the disaster unfolded from the perspective of the operators in the control room of this event. This enactment, with sidebar discussion, was carefully presented on NHK WORLD JAPAN and an obscure detail that if carefully listing can be caught. There is a sister design plant exactly of the same design in the USA. The US plant regularly does a safety exercise in disaster training. The plant has what is endearingly referred to as “PIG TAILS” which are a twin set of pipes exhausting from the reactor building in the event of any failures. When performing test exercises of a reactor disaster failure the procedure also exercises the safety of an exhaust through the “PIG TAILS” which is described as an extremely and purposely disturbing loud sound heard for miles so that the control room operator’s and general public can hear that there is a reactor problem and acts as a warning system, while a controlled shutdown by the operator’s begins and possibly avoid the catastrophe that unfolded in the case of The Fukushima Daachi Nuclear Disaster.

The operator’s in the plant control room lost power, communication and visual contact outside the building and did not know there was any event to respond to. They didn’t know what the sound of the “PIG TAILS” sounded like. In a post analysis debriefing of the sequence of the events, it was discussed that at this plant, there was never any exercises for disaster failure operations for the twenty years in operation, so no one knew what they were confronted with to perform a controlled shutdown. This was a major flaw in safety operations that was shocking to discover. Above all other details that unfolded for this event, this underscores the importance of proper regular training so all personnel and general public know what is occurring and how to react.

Your analysis of the Fukushima nuclear only dealt with operator errors. Why did your article say nothing about the known design flaws in the GE Mark I boiling water reactor particularly with respect to its susceptibility to failure following core meltdowns?

In 1972 Dr. Stephen Hannuaer, an Atomic Energy Commission (AEC) safety official, recommended that the pressure system used in the Mark I boiling water reactor not be accepted for construction permits. Five days after Dr. Hannuaer’s memo the top safety official at the AEC wrote that he agreed with Dr. Hannuaer’s recommendation but rejected it as it, “could well mean the end of nuclear power”. These flaws were well known within General Electric and were so significant that in 1976 the top three nuclear engineers in General Electric resigned over them. A 1985 NRC analysis report of the potential failure of the Mark I reactor under accident conditions concluded that this reactor would likely fail with the first few hours after a core meltdown.

Your article left out the causes of failure related to the known design flaws of the GE Mark I boiling water reactors used at Fukushima.

In 1972, Dr. Stephen Hanuaer, an Atomic Energy Commission (AEC) safety official recommended that the pressure suppression system of the Mark I reactors be discontinued, and any further designs not be accepted for construction permits. Five days Joseph Hendrie, the top safety official at the AEC, agreed with Dr. Hannuaer’s recommendation but then rejected it justifying his rejection because to accept Dr. Hannuaer’s recommendation “could well mean the end of nuclear power…”

In 1976, the three top nuclear engineers at GE resigned over the dangerous shortcomings of the GE Mark I reactor design.

In 1986, Harold Denton, then the NRC’s top safety official, told an industry trade group that the “Mark I containment, especially being smaller with lower design pressure, in spite of the suppression pool, if you look at the WASH 1400 safety study, you’ll find something like a 90% probability of that containment failing”.