What is Magnetohydrodynamics (MHD)?

Magnetohydrodynamics (MHD) – a specialized field that combines fluid dynamics and magnetism – addresses the behavior of electrically conducting fluids, such as saltwater or plasma, under the influence of magnetic fields.

Consider a ship gliding through water with no mechanical propulsion system, but with the push of an invisible force. Such a theoretical application of MHD applied to marine engineering shows how exciting this field can be. By introducing a magnetic field into a conductive fluid like saltwater, a perpendicular force is generated, pushing the fluid in a specific direction. This phenomenon is the Lorentz force in action, and it’s the crux of MHD-based propulsion. When applied on a larger scale, this force can propel massive entities – like ships – without the need for traditional engines, propellers, or turbines.

Using MHD for water propulsion offers numerous advantages. First, the lack of moving parts means reduced wear and tear, potentially translating to lower maintenance costs and longer operational life spans. Additionally, silent operations could be groundbreaking for sensitive marine operations, including research or defense-related ventures. Additionally, beyond water propulsion, MHD has promising potential applications in areas such as wastewater, plasma containment, oil and gas, and more.

However, as with all nascent technologies, there are challenges to overcome, such as the need to ionize water to increase its conductivity, and the energy costs associated with generating robust magnetic fields.

Potential Challenges for MHD in Engineering

• Magnetic Field Strength: Generating strong and uniform magnetic fields over large volumes or distances can be technologically challenging and energy-intensive. The field strength and uniformity are crucial for the consistent and efficient operation of MHD-based systems.

• Materials: The materials used in MHD systems, particularly electrodes in MHD generators or pumps, can corrode or degrade over time, especially when exposed to aggressive fluids.

• Efficiency: While MHD can eliminate moving parts, it doesn’t always mean it’s more efficient. Thermal losses, Joule heating, and other parasitic effects can decrease overall system efficiency.

• Flow Instabilities: MHD-driven flows can experience instabilities, particularly at high magnetic Reynolds numbers. Managing these instabilities is crucial for predictable and efficient operations.

• Complex Simulations: Modeling and simulating MHD flows can be computationally intensive due to the nonlinear coupling between fluid and magnetic dynamics.

Potential Benefits and Applications for MHD in Engineering

• No Mechanical Wear: With no moving parts, magnetic pumps experience minimal wear and tear, leading to longer lifespans and reduced maintenance requirements when compared to traditional pumps.

• Silent Operation: Traditional pumps can be noisy due to their mechanical components. Magnetic pumps operate silently, making them ideal for applications where noise could be an issue.

• Flexibility: The ability to control the flow of liquid by simply adjusting the magnetic field allows for versatile applications in various industries.

• MHD Generators: These are devices that convert thermal energy and kinetic energy directly into electricity. They can be applied in contexts like power plants or space propulsion, especially when integrated with nuclear reactors or other high-energy sources.

• Propulsion Systems: MHD propulsion can be used for marine vessels, allowing for silent and efficient operation. This has potential military applications, especially for submarines.

• Cooling Systems: In nuclear reactors, MHD principles can be used to circulate cooling fluids without the need for mechanical pumps, which could potentially fail under extreme conditions.

• Medical Applications: MHD principles can be used in cardiovascular studies, as blood is a conducting fluid. This can provide insights into blood flow patterns, especially in the presence of magnetic fields used in devices like MRI machines.

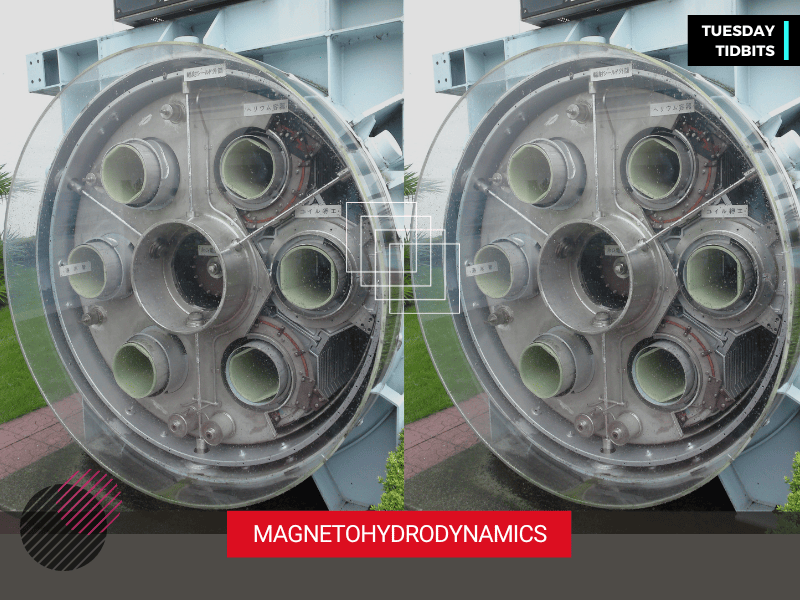

• Plasma Containment: In fusion reactors, MHD is crucial in understanding and controlling the behavior of the plasma. Tokamaks, for instance, rely on magnetic fields to stabilize and confine hot plasma.

• Waste Treatment: MHD can play a role in processes designed to treat and handle waste, especially in separating metallic components from slurry or other waste streams.

• Space Propulsion: MHD thrusters can serve as efficient propulsion systems for spacecraft. The absence of moving parts and the potential for high exhaust velocities make them an attractive option for future space missions.

• Oil Industry: MHD separators can be employed in the oil industry to separate minerals from crude oil, enhancing the purification process.

Final Thoughts

Magnetohydrodynamics is an exciting frontier for professional engineers. While the technology is still evolving, the potential applications and benefits of magnetic pumps in water propulsion are vast. As the field continues to grow, it is only a matter of time before we see more widespread adoption of these revolutionary technologies. So, for all the engineers out there, it’s time to magnetize your curiosity and dive into the future of fluid dynamics!

I was introduced to MHD as a grad student in 1977, The problems noted are still there. Not noted is entropy. Not all of the energy used in the field produces work, ergo there is waste heat – which from MHD is very high.

WOW. Just like the submarine Red October in the Clancy novel!

ATA or possibly now called BlueHalo in Albuquerque has been using this technology for over 25 years producing angular rate sensors can also use as a gyro

A secret soviet submarine with MHD propulsion was at the center of the plot in “The Hunt for Red October” book and movie.