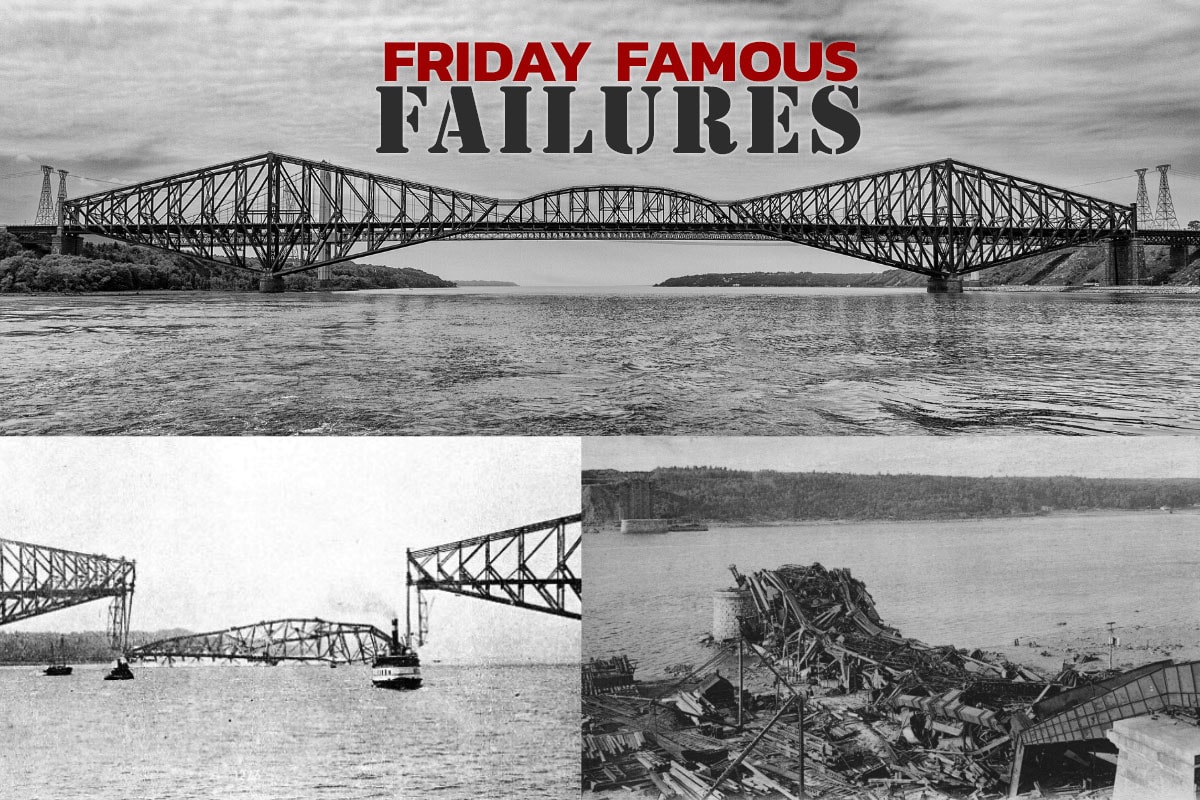

It was one of the world’s most ambitious bridge engineering projects of the time. When completed, the Quebec Bridge would be the longest cantilevered bridge in the world and would connect the busy ports on either side of the St. Lawrence waterway. But before construction was finished, the Quebec Bridge would be marred in tragedy and remembered as one of the worst engineering disasters in Canadian history.

One August afternoon in 1907, construction crews labored under the hot sun. A worker named Beauvais was driving rivets into the southern span of the bridge when he noticed that a rivet he drove in only an hour before had split into two. Beauvais called out an alarm to alert his foreman, but just then an ominous screech of twisting metal arose from the bridge. A large cantilever fell from under him and crashed into the river with a resounding boom. Ten kilometers away in Quebec, people heard the noise and thought they were experiencing an earthquake. Beauvais plummeted into the water with the debris but managed to wrestle himself free. The timekeeper, who was just about to signify the end of the day, had to run from the bridge toward solid ground and reached it only as the girder shattered behind him. A locomotive plunged into the river, but the engineer was pulled from the wreckage by a rescue boat. Others were not so fortunate: 75 of the 86 workers perished from the initial fall, either crushed by falling steel or drowned before rescue boats could reach them.

How did this ambitious project, staffed by some of the world’s most brilliant engineering minds and builders, result in such tragedy?

The idea of the Quebec Bridge was conceived by entrepreneurs from Quebec City who sought to increase business in the area by connecting two ports on either side of the St. Lawrence waterway. Although the Quebec Bridge Company was formed in 1887, no work occurred until the group received federal and municipal funding in 1900. The company then engaged the Phoenix Bridge Company of Phoenixville, Pa to help build the structure. With the support of the Canadian government, who wanted to establish a National Transcontinental Railway from Moncton to Winnipeg, the bridge project moved forward. The Phoenix Bridge Company presented a design for a 150 foot cantilevered bridge that would offer transportation for rail, cars and pedestrians.

Hoping to hire the best, the Quebec Bridge Company hired Theodore Cooper, an American bridge designer famous for his prestigious projects, including the Second Avenue Bridge in New York City. Cooper had a reputation of both brilliance and arrogance. Cooper endorsed the design of Peter L. Szlapka of the Phoenix Bridge Company as the “best and the cheapest,” and further decided to lengthen the center span from 1,600 to 1,800 feet.

Before the start of construction, a Canadian government engineer reviewed Cooper’s plans and criticized the additional length. While the Canadian government hoped to hire their own engineer to assist and review plans, Cooper grew angry, stating that to do so would be to “put him in the position of subordinate, which I cannot accept.”

Yet Cooper had no interest in supervising the work onsite, and chose to remain in his New York City office. Instead, he entrusted the onsite work to Edward Hoare, the chief engineer and Norman McLure, the inspecting engineer for the Quebec Bridge Company, neither of which had experience in such a massive engineering undertaking.

By 1907, the lack of leadership and oversight was showing in the bridge structure itself, most notably in the lower outside horizontal pieces that ran alongside the bridge. That June, McLure informed Cooper that there were errors of alignment in some of the chord splices on the south anchor arm and they were being corrected by moving them into line. Cooper responded that it was not serious, remarking only that, “It would be well to draw attention to as much care as possible in future work to get the best results in matching all the members before the full strains are brought upon them.” Later, in August, McLure telegraphed Cooper to notify him of further issues in the south anchor arm, including that some of the lower chords were bent. This time acting with concern, Cooper asked McLure to investigate. By August 27, the misalignment of the chords was plainly visible. Despite this, the Phoenix Bridge Company did not halt construction.

Hoare, the chief engineer, convinced McLure to visit Cooper in person at his New York City offices to explain the issues. After their meeting, Cooper telegraphed the Phoenixville contracting company, instructing them to add no more load to the bridge until there was an investigation into why the chord splices were bending. Cooper assumed this message would be sent to Quebec City, as well, but the message was never sent.

McLure then met with the Phoenixville Bridge Company offices and they all decided to reconvene the following day. Just as McLure was leaving the meeting at 5:37 pm, the Quebec City Bridge suddenly collapsed. The south anchor arm, the partially completed suspended area, and the cantilever arm fell 150 feet into the St. Lawrence River, killing 75 of the 86 workers. Those who perished included the famed Mohawk steel workers of the Caughnawaga reserve in Lachine, Quebec. The collapse resulted in damages estimated at over $1.5 million. The disaster happened in just 15 seconds.

Immediately a Royal Commission was formed to conduct an inquiry into the cause of the disaster, which included eyewitness testimony from the survivors. The Commission concluded that the “collapse of the Quebec Bridge resulted from the failure of the lower chords in the anchor arm near the main pier. The failure of these chords was due to their defective design.” The Royal Commission attributed the grave errors to designing engineer Peter L. Szlapka and to Theodore Cooper.

Despite this tragedy, the plans for the Quebec Bridge would continue. Once again, the bridge construction resulted in more deaths. On September 11, 1916, soon after it was lifted in place, the southwest corner of the span tore away and sagged. A few seconds later, the other ends pulled off their supports and the whole span came loose and disappeared into the river. Thirteen men were carried to their deaths and several others were injured. The second tragedy resulted from the failure of a casting in the erection equipment that temporarily supported the southwest corner of the span.

The aftermath of the Quebec Bridge collapse of 1907 did inspire significant safety changes in construction. The disaster sparked the establishment of the American Institute of Steel Construction (AISC) and the organization that would later become the American Association of State Highway and Transportation Officials (AASHTO). In Canada, all graduating engineers receive the Iron Ring to serve as a reminder that no matter how technologically advanced engineering practices become, their fundamental duty is to prevent disaster.

Excellent example of cautious and constant on site monitoring of construction to actually observe unanticipated problems, follow through and remedy the issue before proceeding further without regard for political pressure. Safe designs and construction first and foremost!

This is an excellent reminder of the pitfall of hubris.

Every regulation is written in blood. I read that somewhere for aviation, and it holds true for construction as well.

It is too bad the US graduating engineers are not presented with a similar iron ring to remind us of our awesome responsibility. There is an old saying “Neglect Doctors kill one at a time; neglect engineers kill hundreds at a time.”

In the USA, graduating engineers can choose to be conferred into the “Order of the Engineer”. An oath is sworn and a smooth s/s ring is given in the ceremony. I took mine at UB School of engineering and applied Science.

All:

I don’t know enough to really comment on the Quebec Bridge collapses. It would have been nice that, at the time, there was someone as part of the construction crew that knew enough to say: “This doesn’t look right.”

In my past, I have dealt with a similar, but fortunately only annoying situation, regarding hammerhead piers for highway bridges. Early in one of my projects, there was some missive about design deficiencies regarding hammerhead bridge piers directed to all the client’s designers.

Having seen nothing further, I kind of stuck this in a file drawer somewhere, assuming someone else would deal with it. As it turns out, nobody dealt with it.

Then, some of my people found that there were cracking problems with the hammerhead piers. Ultimately there were major redesigns. You can see them today with the concrete “wings” at some of the piers. Note that there were adjacent highway projects with the same problem. Fortunately this turned out to be an expensive annoyance, not a disaster.

My point, and my point to all engineers in the future: If you see something that indicates that there may be a problem with your project, don’t do as I did. Ask questions. Find the people who should deal with the problem and bring the problem to their attention.

Robert Bunce, PE

Thanks. Because this happened in Canada, not well known in US

Because the accident happened in Canada, this disaster is not well known in US.

Did the design use Young’s Modulus to calculate strains? This is just about the time that stress and strain were resurrected from Hook’s Law. As one person stated, prior to Young’s Treatise that correlated stress to strain, the question is NOT why did this bridge collapse, rather, why have many more bridges NOT collapsed.

For the 1916 collapse, there is an explicit photo showing the broken casting but mostly the retaining steel angles structure twisted clockwise. This is the absolute proof that the breaking forces on this joint were exerted in rotation on a horizontal plane. Meaning that the suspension point at cantilever extremities were not vertical relative to the central section. This is most likely the result of opposite directions “elastic instability lateral deflections”. Exactly the still ignored, inherent technical cause for the 1907 catastrophe. This as per Stephen Thimoshenko findings. And I am now witnessing by numerous inter-rivet buckling plus major cracks on the north-west main post after the owners increased substantially the weight of bulk convoys following a harbour development .