This post was updated August 28, 2023 correcting the date of the event from June 28, 1973 to December 22, 1977.

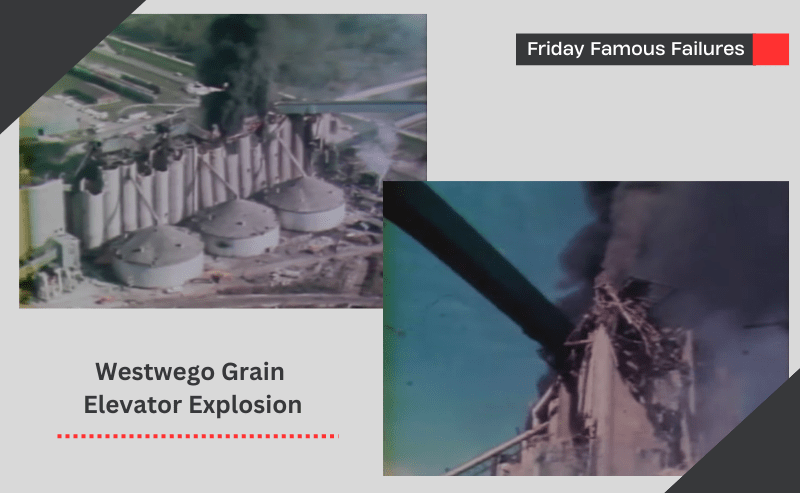

On the morning of December 22, 1977, the small town of Westwego, Louisiana was rocked by a massive explosion that left 36 people dead and over 70 injured. The cause of this tragedy was a grain-dust explosion at the Continental Grain Company facility, which was one of the largest grain elevators in the country at the time.

Grain-dust explosions are a common and deadly occurrence in the grain industry, caused by the ignition of fine, dry particles of grain dust. These explosions can be triggered by a variety of sources, including electrical sparks, open flames, or even hot machinery. Once ignited, the explosion can spread rapidly through the dust-filled air, causing devastating damage to buildings, equipment, and people.

The Westwego explosion was one of the deadliest grain-dust explosions in history, and it had a profound impact on the industry and the community. In the aftermath of the disaster, investigators worked tirelessly to determine the cause of the explosion and to prevent similar tragedies from occurring in the future.

The Continental Grain Company facility in Westwego was a massive complex that included several grain elevators, a barge-loading terminal, and a processing plant. On the morning of the explosion, workers were busy loading a barge with soybeans when the blast occurred. Witnesses reported hearing a loud boom and seeing a massive fireball erupt from one of the grain elevators.

The explosion was so powerful that it blew the tops off several of the elevator silos, sending debris and flames shooting hundreds of feet into the air. The force of the blast shattered windows in nearby homes and businesses, and the shockwave was felt for miles around.

Emergency responders rushed to the scene, but their efforts were hampered by the intense heat and flames. It took several hours to bring the fire under control, and many of the victims were trapped in the burning rubble of the grain elevators.

The exact cause of the explosion was never determined with certainty, but investigators believe that it was likely sparked by an electrical short circuit in one of the conveyor belts that carried the grain through the facility. The conveyor belt system was outdated and poorly maintained, and there were several other potential ignition sources in the facility, including welding equipment and electrical motors.

The Occupational Safety and Health Administration (OSHA) conducted a thorough investigation of the Continental Grain Company facility and found numerous safety violations. The company was fined over $500,000 for these violations.

In the wake of the disaster, there was a renewed focus on safety in the grain industry. The Occupational Safety and Health Administration (OSHA) created new regulations that required grain elevators to implement safety measures such as regular cleaning, proper ventilation, and the installation of spark detection systems.

The disaster also led to the development of new technologies and equipment designed to prevent grain dust explosions. For example, many elevators now use explosion-proof electrical equipment, and some have implemented explosion suppression and isolation systems to prevent explosions from spreading.

The tragedy also had a profound impact on the community of Westwego. The town was small and tight-knit, and many of the victims were local residents who worked at the grain elevator. The loss of so many lives was a devastating blow, and the town rallied together to support the families of the victims and to rebuild in the aftermath of the explosion.

Today, the Continental Grain Company facility in Westwego no longer exists, but the memory of the 1977 explosion lives on. It serves as a tragic reminder of the dangers of working in the grain industry and the importance of safety regulations and proper maintenance. While much progress has been made in improving safety in the decades since the Westwego explosion, there is still much work to be done to ensure that such tragedies never happen again.

I did engineering work at that facility prior to the explosion and have first-hand knowledge of the conditions there. One of the worst aspects of the facility layout was a significant contributor to the high death toll. The small 2-story building that housed offices, worker locker rooms and grain testing labs was located immediately adjacent to the headhouse. The headhouse was a roughly 500 foot tall reinforced concrete structure that housed numerous vertical bucket elevators and grain sampling systems. That structure colapsed onto the 2-story building where many people were working at the time.

Lesson to be learned: Think through the worst case scenarios and make appropriate common-sense adjustments. Had that building been located a reasonably safe distance from the headhouse, the loss of life would have been much lower.

Dust explosion have become too common-place. Unfortunately, insufficient there has been knowledge from building owners and engineers about this hazard. Nfpa is currently realigning its codes to better address this issue.

The Fire Protection Professional Engineering Discipline is best geared to address such hazards and should be part f the project team.

The article states that the Continental Grain Company facility in Westwego no longer exists, but I believe that facility is owned and operated by Cargill today. They do not load barges. They unload out of barges and load into large ships to transport grain around the world. There are several facilities like this along the lower Mississippi that transfer grain from barges to larger ships that can’t travel north of Baton Rouge, La.

After the Libyans sabotaged the Pan Am flight over Lockerbie, a colleague and I discussed several mitigation ideas. One of the ideas was blow out panels. Essentially panels are designed to shear at a certain pressure level. This level would be such that primary structure would remain intact and the pressures to other structure would be mitigated.

I did not see any comment or discussion of this inthe article

In working spaces with poor cleaning protocols, you can have a double whammy. A smaller, localized deflagration creates a shockwave in the interior that shakes loose and suspends dust collecting on all the horizontal surfaces, and this in turn is ignited for an even bigger boom.